Desoldering Braid Wick Tool – Fast, Clean Solder Removal for PCB Repair

Desoldering Braid Wick Tool makes solder removal fast and clean, giving you precise control over every repair. This dependable wick helps you refresh pads and components with confidence.

Desoldering Braid Wick Tool – Benefits for You

✅ Quickly absorbs molten solder so you complete repairs in less time.

✅ Reduces heat stress on delicate pads so your circuit boards stay protected.

✅ Draws solder efficiently thanks to its tight weave, letting you clean joints with fewer passes.

✅ Helps keep your workspace tidy by leaving minimal residue, so cleanup is simple.

✅ Offers long-lasting reliability, meaning you always have a trustworthy tool for repeated sessions.

Upgrade your repair workflow with a wick designed to make every desoldering task smoother.

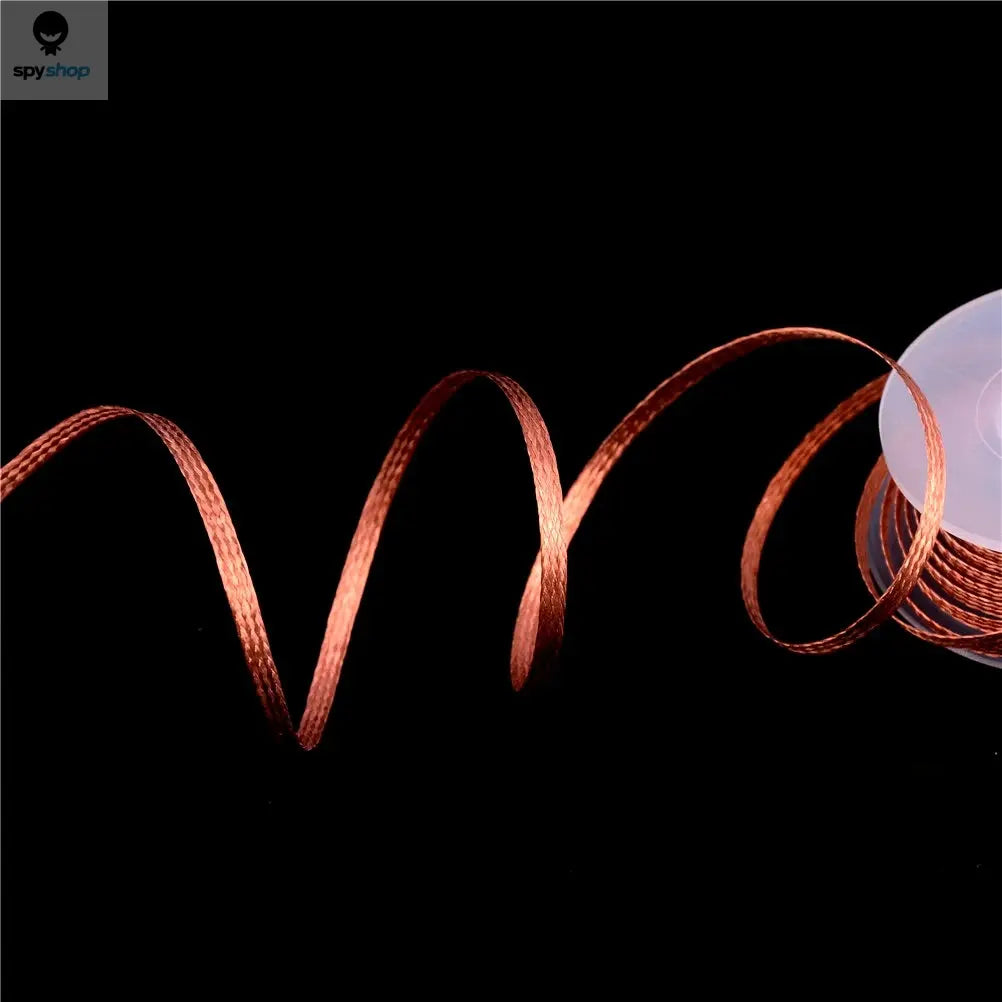

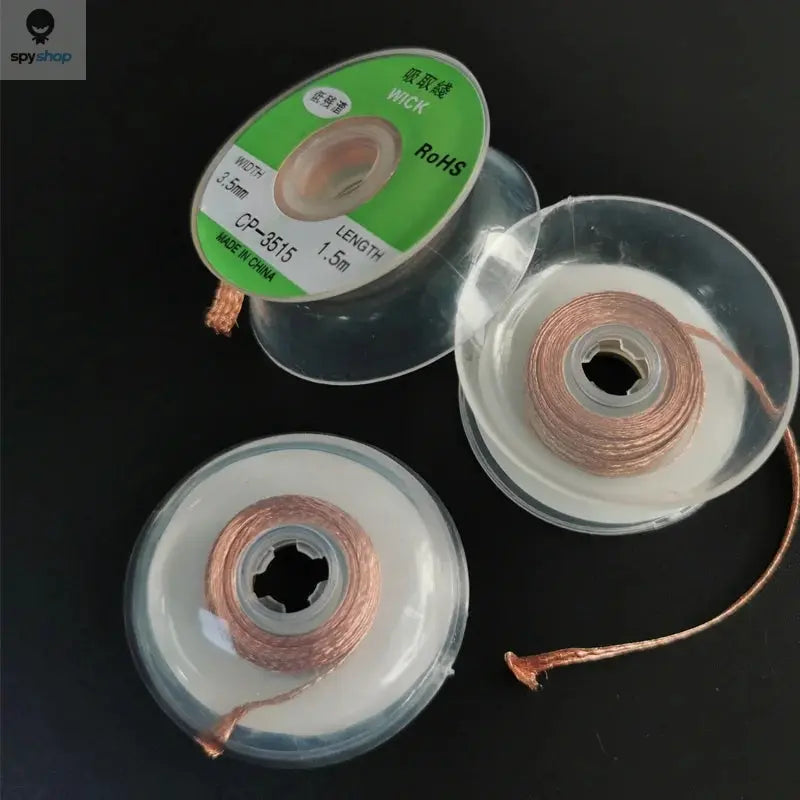

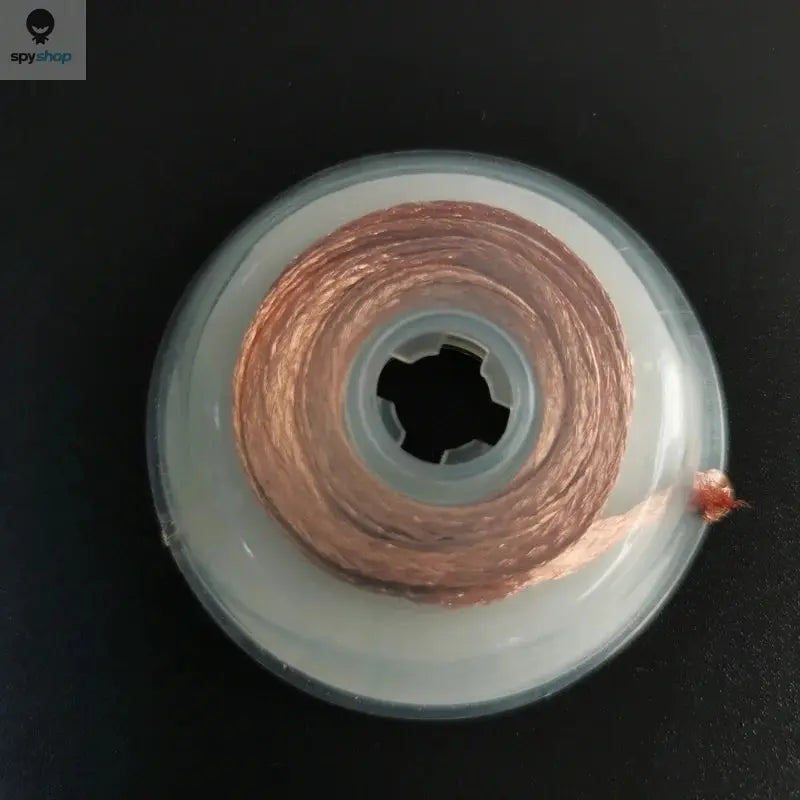

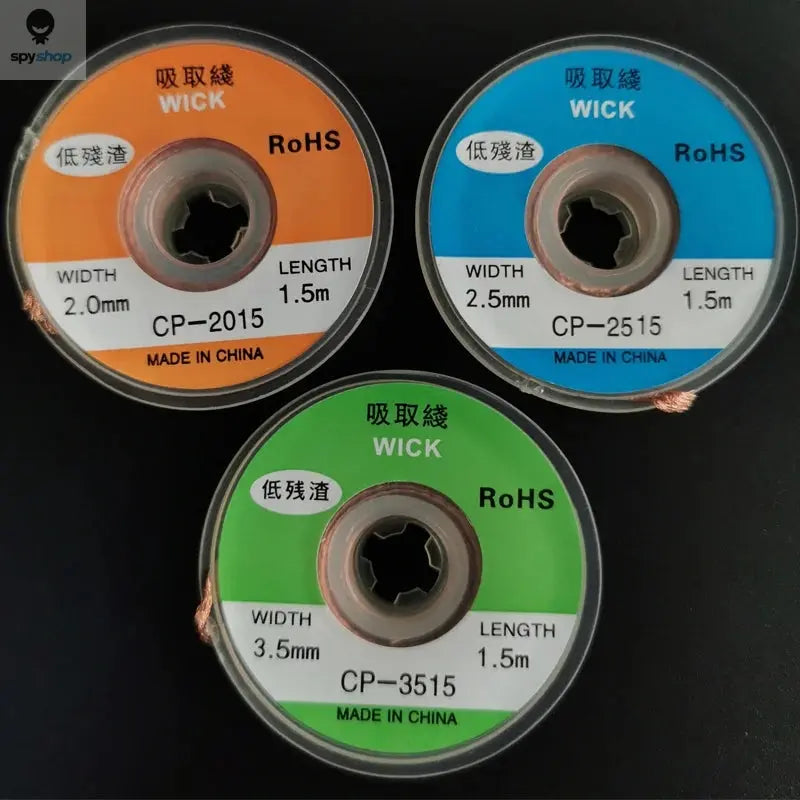

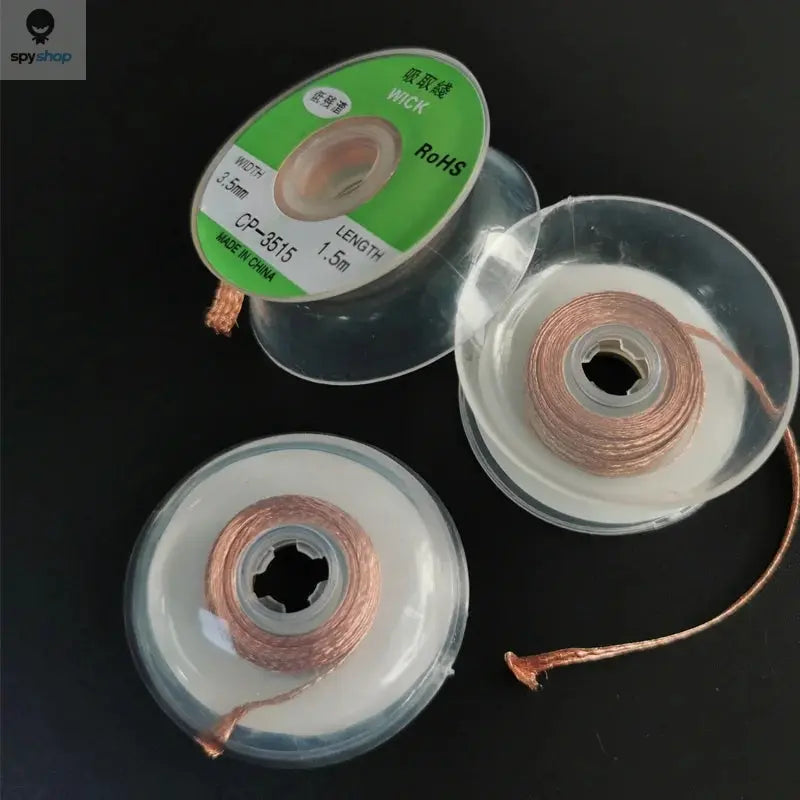

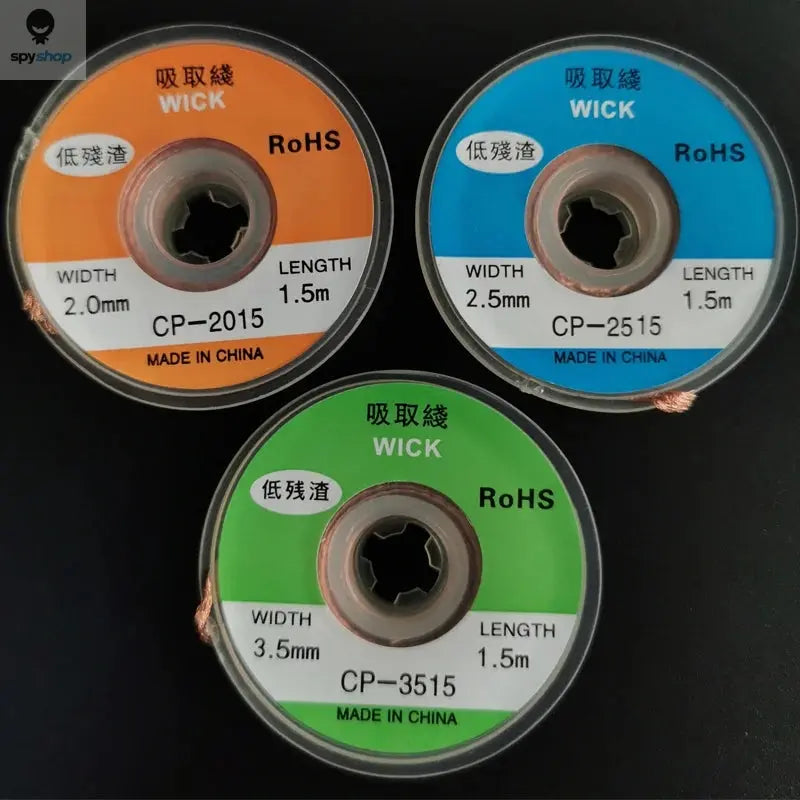

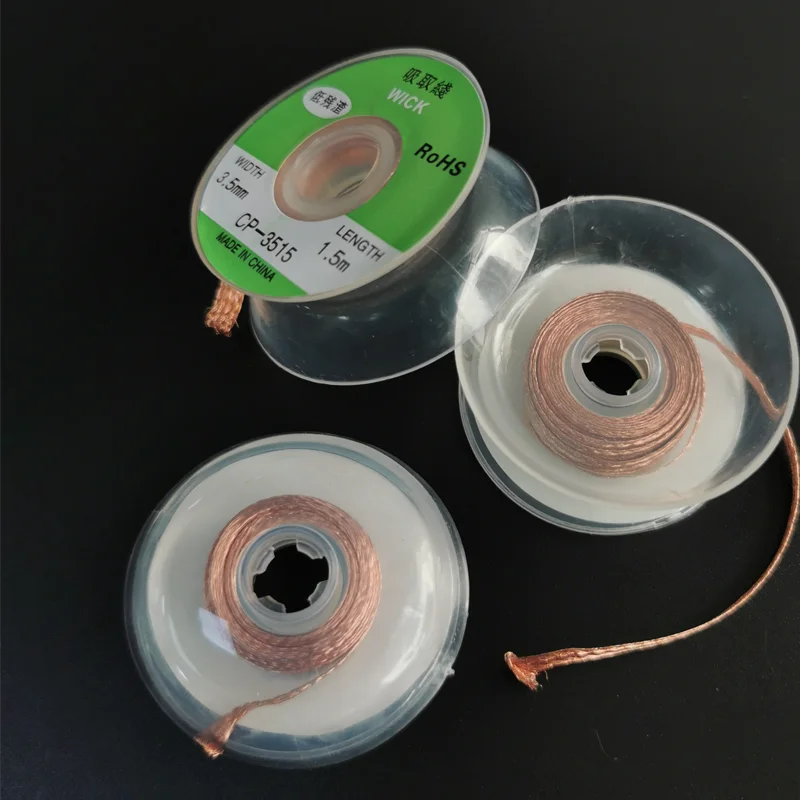

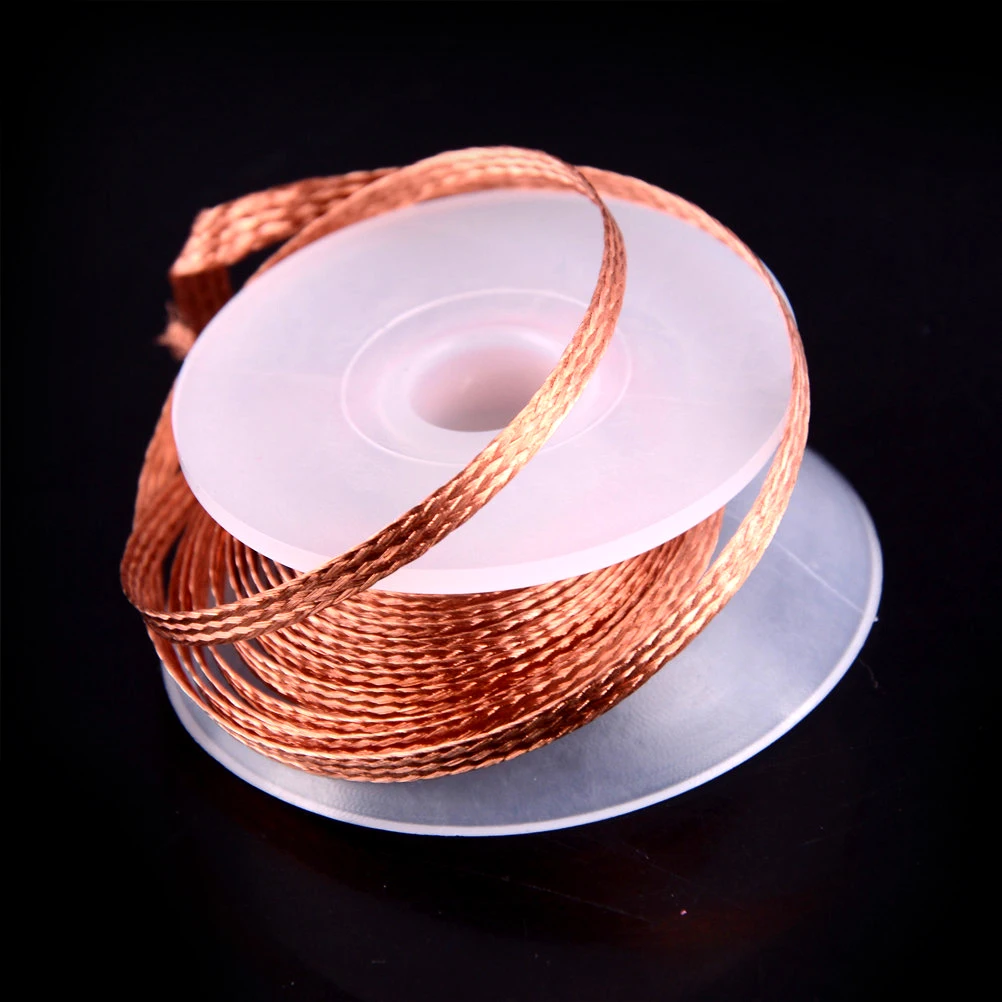

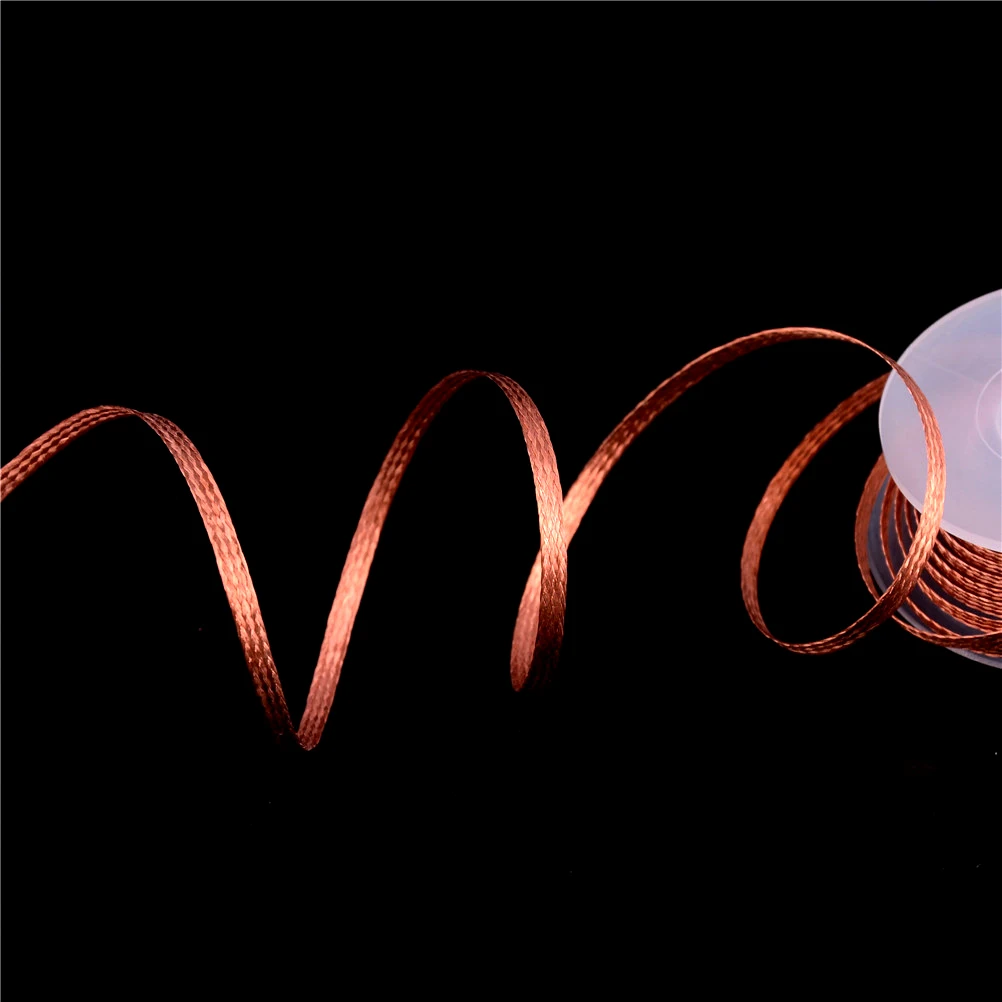

This desoldering braid comes in a 1.5‑meter coil, giving you plenty of length for multiple projects. Its tin‑coated copper strands conduct heat efficiently, allowing solder to melt and wick into the braid almost instantly. Whether you’re removing solder from fine‑pitch IC pins or clearing larger joints, the available 2.0mm and 3.5mm widths adapt easily to different tasks.

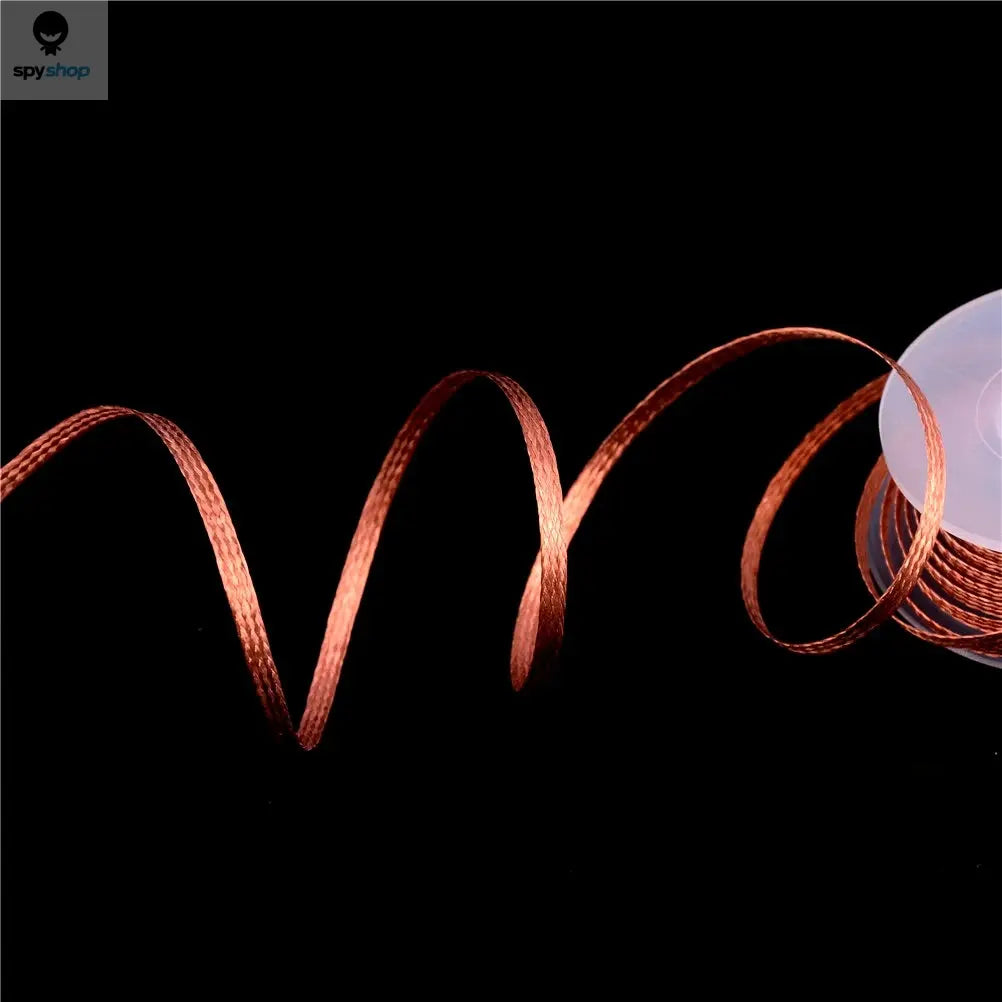

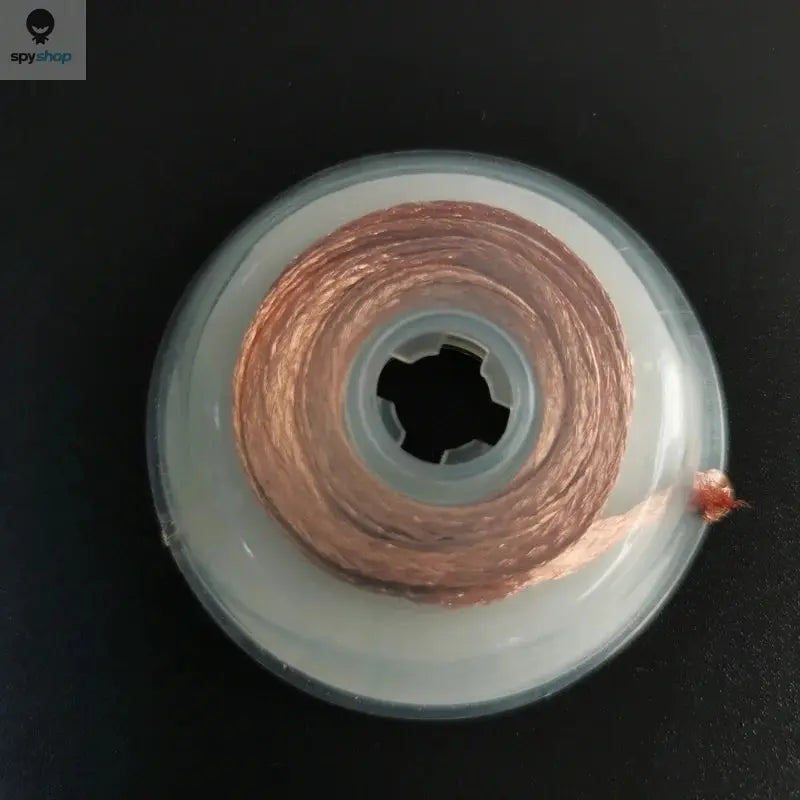

The braid’s structure is engineered to maximize capillary action, meaning molten solder is pulled upward quickly as soon as your iron touches the surface. This gives you cleaner pads with fewer attempts, reducing the chance of damaging sensitive components. Electronics hobbyists, repair technicians, and prototype builders will appreciate how smoothly it handles repeated heating cycles.

Its compact spool fits naturally into your toolkit or drawer, keeping your workstation organized while providing instant access whenever repairs arise.

The fine copper weave ensures consistent capillary action, making each section of braid equally effective.

Its uniform coating helps the strands heat evenly, improving solder flow from joint to braid.

Using shorter segments for each job maintains optimal wicking performance and reduces waste.

The braid’s flexibility helps it lay flat against pads for consistent heat transfer.

When paired with a temperature‑controlled soldering iron, it provides smooth and predictable results.

You can easily trim fresh sections as needed, keeping your work efficient.

Each use leaves the underlying pads cleaner, setting you up for solid re‑soldering later.

The braid’s thermal properties help it heat quickly for responsive solder removal.

It’s well suited for fine‑detail electronics work where accuracy matters.

Cleaner joints mean you can reassemble components with greater reliability.

Its coated copper resists oxidation, helping the braid perform consistently over time.

Use it across repairs, restorations, and prototyping without switching tools.

Its manageable width makes it easy to position exactly where you need it.

Fast wicking helps prevent overheating surrounding areas.

Every section of the braid works consistently, giving you predictable outcomes.

Even beginners can achieve clean results with minimal practice.

As you press the heated iron over the braid, solder flows upward smoothly.

This method keeps surrounding traces cleaner compared to using suction tools.

It works especially well for clearing pads before installing replacement parts.

Even stubborn solder spots can be cleaned with steady pressure and fresh braid.

Using moderate heat helps protect delicate boards while still clearing joints fully.

With practice, you can achieve consistently neat pads ready for reflow.

The compact coil packaging keeps the braid protected and easy to dispense.

Equip your toolkit with a reliable desoldering solution and make every repair feel effortless.

Choose options